Built Fast. Built to Last.

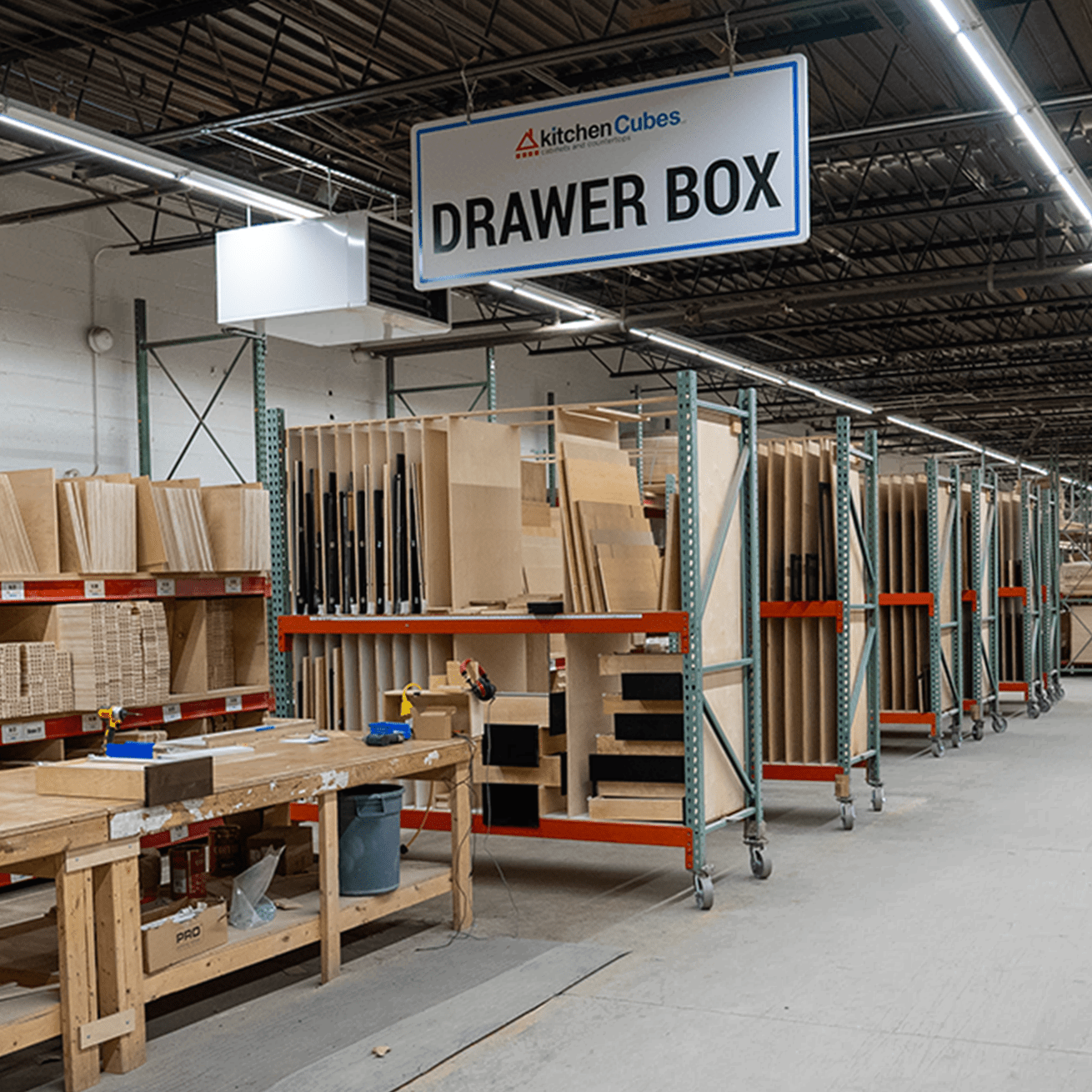

Kitchen Cubes Production

Once a Kitchen Cubes order is placed, it takes our production team just four days to complete it. And we make sure it is up to our high standards every step of the way.

Pro-Grade Guarantee

The Kitchen Cubes Promise

Made in the USA

All Kitchen Cubes cabinets are made right in the USA.

Affordable Pricing

Don’t break the bank for cabinets.

Quick Delivery

Fast delivery from our own trucks.

Factory Direct

Straight off the line. No distributors needed.

Easy Installation

Prebuilt cabinets ready to be installed.

Local Support

Our team is here to help when you need it.

Day 1: Material and Rough Carpentry

All Kitchen Cubes products are assembled by hand at our Bristol, Wisconsin facility. Our craftsmen begin by selecting the right material for the project. Kitchen Cubes cabinets are built with either solid maple, plywood particle board, or birch – materials that can stand up to the wear and tear of everyday life. For certain products, like doors, Kitchen Cubes only uses solid maple frames and doors for all seven colors we offer.

We begin construction with a large 4'x8' sheet of the desired material and cut it down to the order’s component sizes. We optimize and cut maple wood sticks for doors and frames. Next, we add dados and system holes, followed by shaping, sanding, and assembling the door parts. Lastly in this step, we organize all unfinished frames, doors, and drawer heads by color groupings.

Solid Maple

Plywood

Particle Board

Birch

Day 2: Finishing, Color, and Coating

Once the parts are assembled, all frames, doors, and drawer heads go through a state-of-the-art Cefla surface finishing system to ensure they look their best. Each time a part passes through the finishing system, it is sanded, cleaned, heated, sprayed, baked, and UV cured. For painted colors, we run each part through this system three times; for stained colors, we run each part through five times. We use all water-based UV cured paints, stains, and top coats to finish our cabinets.

Day 3: Sorting and Hardware

We then separate the finished parts and case parts onto large sorting carts. We put order labels in each slot to organize the proper size parts with each cabinet label. After that, we attach hinges, assemble drawer boxes and heads, and attach rails to the drawer boxes. As the sorting carts maneuver through the shop, we add remaining parts to them for assembly preparation.

Day 4: Assembly and Boxing

Now at the assembly stations, we put together parts for each cabinet from the face frame to the back of each cabinet, attach doors, and install drawers. We then place shelves at the bottom of the cabinet and anchor them in place for safe shipping.

Now that assembly is complete, our quality control team reviews each label and cabinet before the production crew boxes up the orders. Lastly, we pack up the orders and prepare them for shipping.

Proudly Made in the USA

Proudly Made in the USA

Kitchen Cubes is proud to say we own our entire operation, from painting to sorting to assembly to packing to shipping. None of our products come from outside the US. We assemble all our cabinets and countertops in our factory in Bristol, Wisconsin where they are shipped directly to you.

Trusted by Hundreds of Building Leaders

View our brochure of Quick Ship products

Browse the Kitchen Cubes product brochure for custom orders.

Get Our Newsletter

No spam, we promise

newsletter

Customers

Support

© 2025 Kitchen Cubes, LLC. All rights reserved.